Jianlong Plastic-32 Years Specializing in Customized Processing of Plastic Pipes and Fittings.

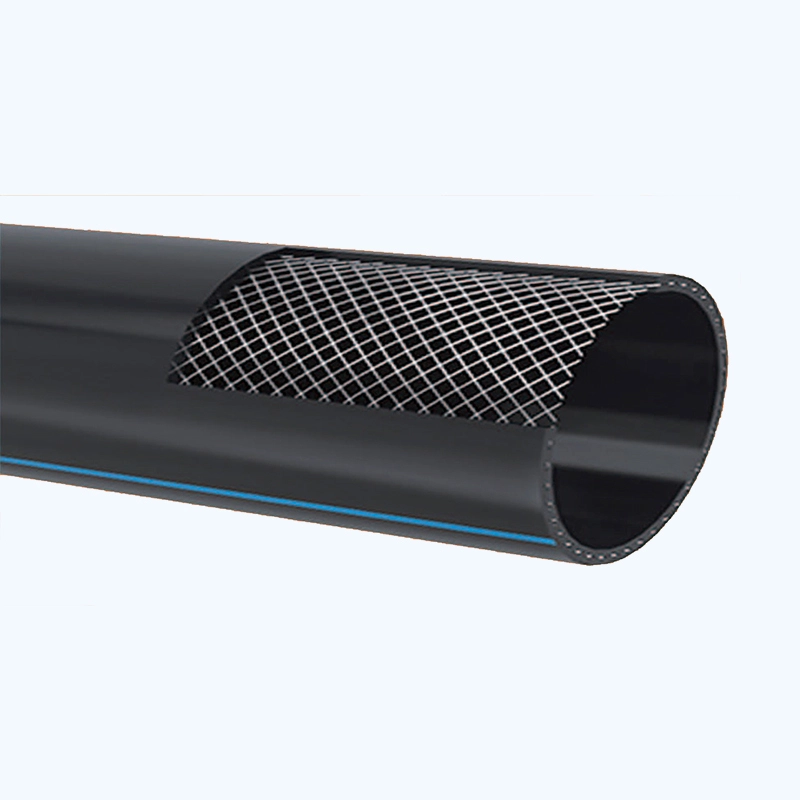

Steel Wire Reinforced PE Pipe For Water Supply High-Density Polyethylene Composite Material

Usage: Water supply

Size: Customizable

Minimum Order Quantity: 1000 pieces

Payment Method: T/T

Delivery time: 10 - 30 working days

Port of Loading: Qingdao Port

Certificates: ISO 9001、ISO 14001、ISO 45001、NSF、CE、SGS

Product Introduction

With excellent pressure resistance and flexibility, the SRTP pipe is ideal for long-distance buried water supply and gas transmission pipeline systems. It uses polyethylene electro-fusion fittings: during connection, the internal heating element of the fitting melts the outer plastic of the pipe and the inner plastic of the fitting, creating a safe and reliable fusion bond.

Multi-Layer Protection: A three-layer integrated structure (inner/outer HDPE + middle steel wire skeleton) combined with adhesive resin prevents delamination and ensures long-term durability.

Anti-Creep Stability: The steel mesh constrains HDPE creep, maintaining high mechanical strength at room temperature, low linear expansion coefficient (35.4×10⁻⁶/℃), and excellent dimensional stability.

Temperature Resistance: Strength loss is <5% per 10℃ temperature rise (far less than pure plastic pipes), adapting to wide temperature variations (-40℃ to 80℃).

Hygienic & Environmentally Friendly: Smooth inner surface prevents scaling, ensuring safe water quality; lead-free, non-toxic, and fully recyclable.

Easy Installation: Electro-fusion connection enables fast, reliable sealing without complex anchoring; flexibility allows above-ground prefabrication and adaptation to rugged terrain.

Long-Life Economy: Designed for a 50-year service life with minimal maintenance, significantly reducing long-term operation costs.

Product Parameters

|

Item |

PE100 Solid Wall Pipe |

Steel Wire Skeleton PE Composite Pipe (SRTP) |

|

Pressure Resistance |

≤1.6MPa |

S3.5MPa (Four-layer structure: ≤7.0MPa) |

|

Flow Capacity |

Flow capacity is 25% higher on average than PE solid wall pipe |

|

|

Weight per Meter |

~40% lighter than PE pipe for the same 1.0Mpa, SRTP:630*23.0:50Kg; PE100:630*374:67Kg |

|

|

Traceability |

Non-traceable (no detection for positioning) |

Traceable (metallic skeleton enables electromagnetic detection). |

|

Linear Expansion Coefficient |

0.15mm/m.C |

0.13mm/m.C |

|

Crack Resistance |

SRTP outperforms PE solid wall pipe in both resistance to rapid crack propagation and resistance to slow crack growth due to the intermediate steel wire skeleton. |

|

|

Comparison Item |

Steel Wire Skeleton PE Composite PipDuctile Iron Pipee |

Ductile Iron Pipe |

|

Sanitary & Environmental Performance |

Less prone to scaling; green and environmentally friendly |

Prone to bacterial growth, causing "yellow water" issues. |

|

Anti-Settlement Performance |

Excellent toughness; superior resistance to ground settlement. |

Poor toughness; prone to cracking or breaking under settlement. |

|

Service Life |

Long lifespan: 30–50 years. |

Short lifespan: 5–30 years |

|

Connection Performance |

Customizable length; fewer joints; no risk of leakage |

Fixed length (6m per segment); numerous joints; poor sealing and high leakage risk |

|

Weight per Meter |

630*23.0(1.0Mpa):50Kg |

635*9.9:147Kg |

|

Construction Period & Cost |

Short construction time; low installation cost. |

Complex construction process; long duration; high cost |

|

Hydraulic Performance |

Pipe wall roughness coefficient: 0.009; strong flow capacity; minimal head loss. |

Pipe wall roughness coefficient: 0.013; poor flow capacity; significant head loss. |

|

Specification (Average Outer Diameter) |

dn50mm~225mm (Customizable) |

|

Color |

Black or as required |

|

Appearance |

The inner and outer surfaces of the pipe shall be clean and smooth, free of defects such as bubbles, scratches, dents, impurities, or uneven color.The pipe ends shall be cut flat and perpendicular to the pipe axis, and the ends shall be sealed. |

|

Pressure Rating |

1.0~3.5MPa |

|

Melt Mass-Flow Rate (MFR) |

The change in MFR (Melt Mass-Flow Rate) of polyethylene before and after processing shall not exceed ±25% (load: 5kg, temperature: 190℃). |

|

Oxidation Induction Time (OIT) |

≥20min(200℃) |

|

Pressure Cracking Stability |

No cracks, delamination, or splitting (test speed: 100mm/min) |

|

Peel Strength |

Average peel strength ≥15N/mm, individual specimen peel strength ≥12N/mm, with ductile failure at the peeling interface and a flocculent surface (test speed: 100mm/min) |

|

Ring cutting static hydraulic strength |

No cracking or leakage in the circular groove after cutting (test conditions: 20℃, 1.5×PN, 165h). |

product Application

Municipal Engineering

Urban water supply, drinking water transmission, building drainage, rainwater collection, heating return pipelines, and gas/natural gas transmission.

Industrial Fluid Transport

- Chemical Industry: Process and discharge pipelines for corrosive media (acids, alkalis, salts).

- Textile & Dyeing: Pipelines for corrosive dyes, slurries, and waste discharge.

- Thermoelectric Engineering: Process water, return water, dust removal wastewater, and industrial slag transport.

- Oil & Gas Extraction: Transport of oily wastewater, oil-gas mixtures, and tertiary oil recovery process pipelines.

- Underground Coal Mines: Water supply, drainage, compressed air, grouting, and gas extraction pipelines.

- Nonferrous Metals: Corrosive media (electrolytes, wastewater) transport in smelting processes.

Building & Fire Protection

Building water supply systems and fire protection pipelines.

Agriculture & Irrigation

Farmland drainage, deep well water extraction, canal pipelines, and irrigation water supply.

Marine Engineering

Seawater transport for desalination plants, coastal city pipelines, submarine pipelines, and optical cable protection conduits.

Shipbuilding

Ship wastewater pipes, drainage pipes, ballast water pipes, and ventilation ducts.

Special Media Transport

Process and discharge pipelines for industrial wastewater, gas slurries, and solid powders.

Links

Products

Contact Us

Contact: Manager Zhang

Tel: +86 17860052961

E-mail: jianlongplastic@gmail.com

Address: Jinger Road, Jiaoshan Town, Ju County, Rizhao City, Shandong Province